This guide has all information you’re looking for about 3 side seal pouches.

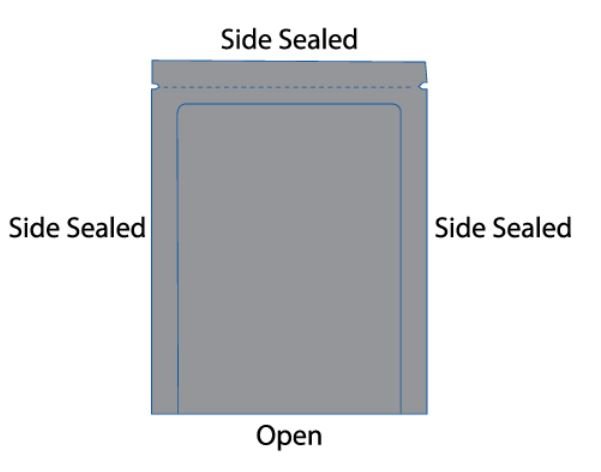

As the name suggests, these pouches are sealed on three sides and only one left open for filling.

Keep reading to learn more about these packaging pouches.

3 side seal pouches have three sealed sides with one part open for filling.

4 side seal pouches have all their four sides sealed.

3 side seal pouches have more packaging capacity than the 4 side sealed pouches.

Since 4 side seal pouches are sealed in all the sides, they have uniformed appearance compared to 3 side sealed pouches.

3 side seal pouches are made from one-piece film while 4 side seal pouches are made from two pieces of film.

3 side seal pouches can be gusseted whereas 4 side seal pouches mostly do not have gusset.

4-sided offer better sealing strength, vacuum finish and product protection compared to 3 side seal pouches.

4 side seal pouches are mostly considered for special packaging as opposed to 3 side seal pouches.

Both 3 side seal pouches and 4 side seal pouches are made from similar materials.

They both have similar packaging characteristics and advantages.

3-side seal pouches have an array of benefits that have revolutionized packaging industry such as:

This in turn does not affect the overall weight hence making transportation inexpensive.

3-side seal pouches cannot be recycled due to difficulty in separating the combined material into single layers.

You cannot use most of them in microwaves.

3 side seal pouches are used for packaging both food and non-food items.

The food items include; candies, chips-snacks, meat, sugar, green peas, etc. Non-food items include; drugs, beauty cream, seeds, toys, among others.

Our 3-side seal pouches are made from layered thermoplastics which are bonded together by an adhesive substance such as vinyl acetate.

All our materials are carefully chosen.

Materials must pass through a quality assessment before they can be used in the manufacturing process.

The chosen materials possess qualities such as;

You can choose up to four film material laminations that best suits your products’ packaging needs.

They include polyethylene terephthalate (PET), foil, kraft paper, polyester (poly), aluminum, nylon, etc.

Some of the layerings we offer are: